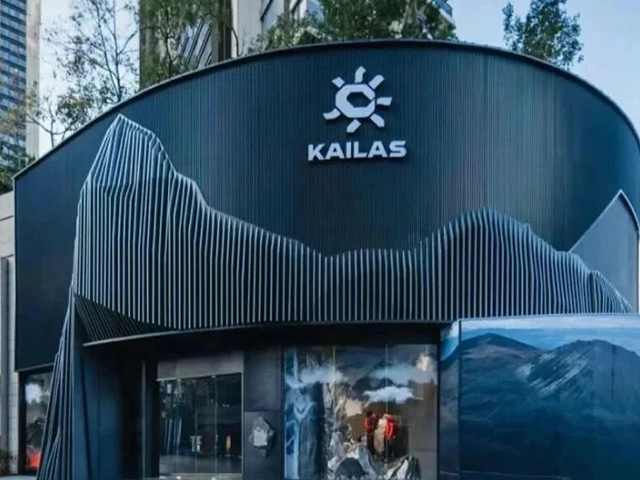

Background

In the high-end consumer market, customers are highly sensitive to factors such as product authenticity, consistency between advertised and actual fabric composition, and whether production processes are environmentally sustainable. At the same time, high-end brand stores typically maintain relatively low inventory levels. When stockouts occur, cross-store inventory transfers rely on manual communication, which is inefficient and error-prone, often leading to the loss of high-net-worth customers. Moreover, traditional anti-counterfeiting methods are easily replicated and fail to meet the demand for uniqueness and transparency among premium customers. Therefore, brands urgently need technological solutions to address three core challenges: the "trust crisis," "inventory lag," and "inventory inaccuracy."

Business Challenges

Trust Issues: High-end products are easily counterfeited, and low-cost imitations flood the market. Customers doubt product authenticity, and traditional anti-counterfeiting tags are easily replicated, affecting repurchase decisions.

Inventory Lag: Store inventories are scattered across multiple warehouses and locations nationwide. Manual stocktaking is time-consuming, and cross-store transfers during shortages are slow, failing to meet the timely needs of high-value customers.

Decision-Making Delays: Traditional inventory reports are not updated in real time, preventing management from making quick purchasing, transfer, or promotion decisions. This often results in overstocking or frequent stockouts.

Solution

One-Item-One-Code Anti-Counterfeiting & Traceability

Each product is embedded with an RFID tag containing information such as production batch, fabric origin/weight, and quality inspection reports. Linked to the ERP quality inspection database, it enables full-chain traceability and authenticity verification.

Efficient Stocktaking & Logistics

RFID devices allow batch reading within range, enabling receipt of goods without unboxing. Logistics warehouses can integrate with automated equipment, significantly improving efficiency, reducing labor, and enabling quick and easy inventory counts.

Real-Time Data Support

The RFID system updates inventory data in real time to the ERP/WMS, allowing management to monitor inventory levels, sell-through rates, and trend forecasts for each store and SKU, ensuring accurate and efficient inventory turnover.

Impact&Results

Achieved 100% item-level traceability

Inventory accuracy rate increased to over 99.9%

RFID channel machine readers process over 600 boxes per hour

Inventory turnover rate improved

RFID-collected real-time product data

Supports precision marketing and display optimization

25 Years of Industry Expertise · RFID Digital Solutions

Focused on the Fashion Industry,

Serving 100+ Fashion Apparel and Footwear Brands