Background

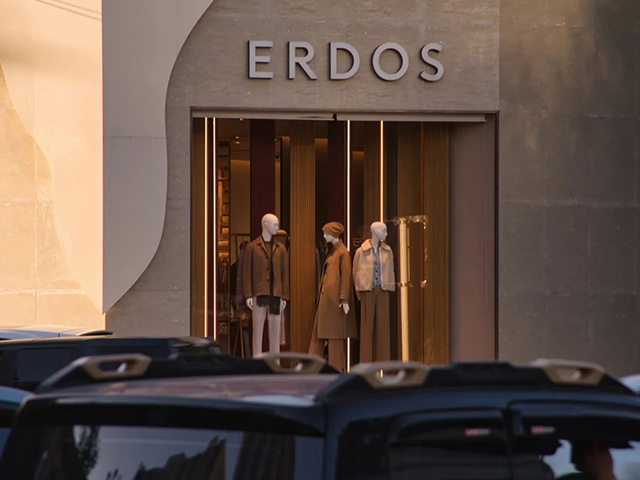

In the luxury market, consumers are highly sensitive to product authenticity, alignment between advertised and actual material composition, and the environmental sustainability of production processes. Meanwhile, high-end brands typically maintain limited in-store inventory. Stockouts often trigger cross-store transfers reliant on manual coordination—an inefficient and error-prone process that risks losing high-net-worth customers. Traditional anti-counterfeiting methods also fall short in meeting demands for uniqueness and transparency. Thus, ERDOS prioritized addressing three core challenges: the trust deficit, inventory latency, and stock opacity through technological innovation.

Business Challenges

Trust Deficit: Premium products are frequently counterfeited, with low-cost imitations saturating the market. Customers question authenticity, and easily replicated traditional anti-counterfeiting tags undermine repurchase confidence.

Inventory Latency: Stock is scattered across nationwide warehouses and stores. Manual inventory checks are slow, and delayed inter-store transfers during shortages fail to meet the expectations of high-value clients.

Decision-Making Lag: Outdated inventory reports prevent management from making agile procurement, allocation, or promotion decisions, leading to recurrent overstocking or shortages.

Solution

Item-Level Authentication & Traceability

Each product is embedded with an RFID tag linked to production batches, cashmere origin/weight, quality reports, and other identity data. Integrated with the ERP quality database, it enables end-to-end traceability and authenticity verification.

Efficient Stocktaking & Logistics

RFID readers allow batch scanning within range, permitting receipt verification without unboxing. Warehouse automation interfaces streamline operations, cutting labor costs and accelerating inventory counts.

Real-Time Data Integration

The RFID system syncs live inventory data to ERP/WMS, providing management with dynamic insights into stock levels, sell-through rates, and demand forecasts per store and SKU, optimizing turnover accuracy.

Impact&Results

Achieved 100% item-level traceability

Inventory accuracy exceeds 99.9%

RFID channel machine process 600+ boxes hourly

Inventory turnover rates significantly improved

Real-time product data captured via RFID

Enables targeted marketing and display optimization

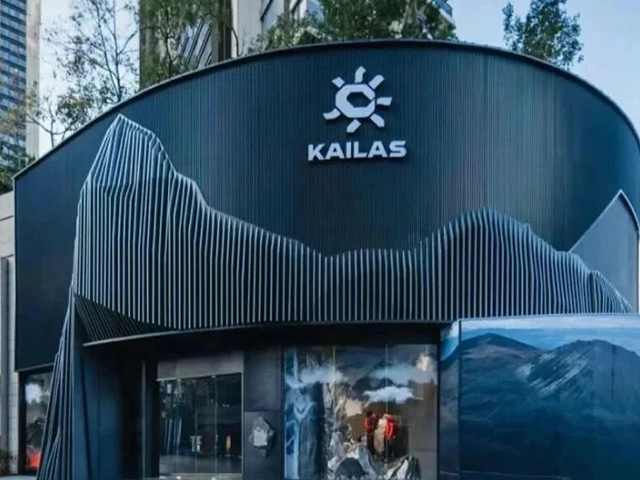

25 Years of Industry Expertise · RFID Digital Solutions

Focused on the Fashion Industry,

Serving 100+ Fashion Apparel and Footwear Brands